Difference between revisions of "3194: 16 Part Epoxy"

(→Explanation) |

(→Explanation) |

||

| (55 intermediate revisions by 19 users not shown) | |||

| Line 10: | Line 10: | ||

==Explanation== | ==Explanation== | ||

| − | {{incomplete|This page was created by a gorilla glue gorilla. Don't remove this notice too soon.}} | + | {{incomplete|This page was created by boiling down a gorilla glue gorilla. Don't remove this notice too soon.}} |

| − | This comic refers to {{w | + | This comic refers to {{w|epoxy}} — substances used as adhesives, sealants, and coatings, named for the chemical substructure {{w|epoxide}}, which is the precursor component to these substances turning from liquids to solids. |

| − | The title text references how not all epoxies and glues work on every material, and that applying them on | + | [[File:FiveMinEpoxy.jpg|thumb|A typical 2-part epoxy applicator.]]Many types of epoxy are multi-part (usually two-part), where the components, such as {{w|resin}} and a {{w|Epoxy#Curing|hardener}}, are stored separately. For ease of use, this can be in parallel syringes (of equal volume, or proportionately different widths to maintain the correct mixing ratio) such that the user squeezes out both of the separate chemicals onto the initial surface, or into a container, by depressing both syringes simultaneously. The user then thoroughly mixes the components, as quickly as possible. The mixture is spread over the surface(s) to be joined or protected, and/or into the gaps to be filled, and if there are separate surfaces involved they are quickly positioned and held in place. The combined epoxy cures quickly, usually within a few minutes. This comic presents a fictitious 16-part epoxy, with the same apparent logic of parallel deposition in mind, with many components that are implausible or make fun of common problems people have when using epoxy in real life. |

| + | |||

| + | The title text, as with a couple of the substances involved, references how not all epoxies and glues work on every material, and that applying them on others can also require special techniques or products to gain the best advantage. Some industrial or industrial-grade adhesives contain solvents (e.g. {{w|tetrachloroethylene}}, which is used in E6000 glue) that release harmful vapors as they cure. If used improperly, this can result in the release of chemical vapors in an enclosed space along other dangerous side-effects, while also ''still'' not adhesing<!-- https://thecontentauthority.com/blog/adhere-vs-adhese --> as intended. | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 38: | Line 40: | ||

|Softener | |Softener | ||

|{{Yes}} | |{{Yes}} | ||

| − | | | + | |The word is probably being used in humorous contrast to the "hardener" component, and perhaps also by analogy with laundry products that contain a fabric softener alongside a detergent. However, {{w|plasticizer|plasticizers}} are often added to polymers to make them more pliable, and thus to increase their impact resistance. These plasticizers tend to be lost over long periods of time (e.g. by evaporation or degradation), which contributes to old plastic becoming brittle. |

|- | |- | ||

|Rosin | |Rosin | ||

|{{Yes}} | |{{Yes}} | ||

| − | |While this looks like a joke entry, this is actually | + | |While this looks like a joke entry, this is actually a different kind of resin which is extracted naturally rather than synthesized from other chemicals. Rosin (a kind of '{{w|Flux (metallurgy)|flux}}') is one of two parts that make up rosin-core solder, used in electronic work, where the rosin is located in the center (the "core") of the wire-like solder, similar to how graphite is in the core of a pencil. When heated hot enough to melt, it {{w|Soldering#Flux|cleans corrosion and oxides from the surfaces}} of the metal parts to be joined, creating bare metal surfaces that can be 'wet' by the solder. In rosin-core solder, the two substances are touching rather than kept completely separate, since they're both in solid form, and don't react with each other even when they're heated to melt them. In this respect they differ from common combination epoxy chemicals that will be both liquids that cure together on contact even at room temperature. Rosin is also frequently applied to the bows of string instruments like violins or cellos to improve the sound, as immortalized in the famous song "{{w|The Devil Went Down to Georgia}}" or the folk song {{w|Old Rosin the Beau}}. |

|- | |- | ||

|Stuff that bonds permanently to skin and nothing else | |Stuff that bonds permanently to skin and nothing else | ||

|{{No}} | |{{No}} | ||

| − | |One key annoyance with sticky substances is the difficulty of removing them when they | + | |One key annoyance with sticky substances is the difficulty of removing them when they are inadvertently applied to skin. In hyperbole, we have a substance here that seems to bond *solely* to skin. This may be a reference to {{w|cyanoacrylate|cyanoacrylate adhesives}} ("super glues"), which famously bond quite aggressively to skin (sometimes to positive effect, for medical applications!) due to being moisture-activated, while often failing to bond the target materials. Still, none are known to bond to skin exclusively.{{acn}} |

|- | |- | ||

|Stuff that will crack and turn white over a few days, for decorative appearance | |Stuff that will crack and turn white over a few days, for decorative appearance | ||

|{{Maybe|Not effective as epoxy}} | |{{Maybe|Not effective as epoxy}} | ||

| − | | | + | |Poor finish, where an intended smooth uniform surface cracks or discolors, can be a frustrating problem when applying epoxy mixtures to visible surfaces — especially when the problem only appears some time after you've congratulated yourself on a job well done. This humorously describes this as an intended effect, although there are situations where this truly may be intended. 'Crackle effect' is a real thing for crafters, often created by mixing paint and glue, and an adhesive used to join two pieces or repair a crack or break can be modified for a deliberately cracked or discolored surface to match the other surfaces. |

|- | |- | ||

|Placebo | |Placebo | ||

|{{Maybe|Not in the field of adhesives}} | |{{Maybe|Not in the field of adhesives}} | ||

| − | |The {{w|placebo effect}} happens when somebody is told that something has a certain effect, when in reality | + | |The {{w|placebo effect}} happens when somebody is told that something has a certain effect, when in reality it has no mechanism of action to produce that effect. This is commonly used in medical studies to determine whether a medication actually does something, as opposed to simply having a {{w|psychosomatic effect}}. Using this term to describe a type of polymer suggests it would make someone believe it is gluing things together without actually doing anything, which is unlikely. Alternatively, this could refer to a component or filler that claims to serve a specific purpose while having no true benefit, merely causing the perception of benefit to the consumer (and presumably causing better reviews). |

|- | |- | ||

|Minced duct tape | |Minced duct tape | ||

|{{Maybe|Not intentionally}} | |{{Maybe|Not intentionally}} | ||

| − | |{{w|Duct tape}} is widely used as a way to join and/cover things, sometimes in contexts where an epoxy might provide a more high-quality solution. [[Randall]] is pretending that having very small pieces of tape in the mix would add to the epoxy's ability to hold things together. In reality, cutting duct tape into small pieces would weaken it and make it ''less'' effective at sticking things together | + | |{{w|Duct tape}} is widely used as a way to join and/or cover things, sometimes in contexts where an epoxy might provide a more high-quality solution. [[Randall]] is pretending that having very small pieces of tape in the mix would add to the epoxy's ability to hold things together. In reality, cutting duct tape into small pieces would weaken it and make it ''less'' effective at sticking things together. |

|- | |- | ||

|Acetone fragrance | |Acetone fragrance | ||

|{{No}} | |{{No}} | ||

| − | |Acetone is a volatile solvent used in a number of glues and paints ( | + | |{{w|Acetone}} is a volatile solvent used in a number of glues and paints (including nail polish), but it weakens epoxy and can even be used to remove uncured epoxy. It has a strong, distinctive smell, and is actually toxic, making fragrance an odd reason for adding it to any product. It ''would'' give the epoxy a familiar "chemical smell" that people associate with industrial compounds. The use of 'X fragrance' in an ingredient list, instead of simply listing the ingredient X, usually implies that the actual ingredient is some (cheaper) substitute for X with a similar scent. Since acetone is already inexpensive, perhaps some substitute has been discovered that provides the smell without weakening this glue, though that seems unlikely given the context. |

|- | |- | ||

|Powdered bar magnets | |Powdered bar magnets | ||

| Line 74: | Line 76: | ||

|2-Polyethylvinylesteracetate | |2-Polyethylvinylesteracetate | ||

|{{Maybe|Unclear}} | |{{Maybe|Unclear}} | ||

| − | |This sounds almost exactly the same as the above item, but {{w|2-Polyprenyl-6-hydroxyphenol methylase|a name with a "2-" prefix}} generally indicates that the initial bit of the name is a {{w|functional group}} attached to the ''second'' position along a chemical chain (often being the carbon-carbon 'spine' of a molecule, in large-molecule organic chemistry), rather than attached to its end. Because the molecule name is (possibly deliberately) malformed, it's hard to tell what is supposed to be attached to the second carbon of what subunit. | + | |This sounds almost exactly the same as the above item, but {{w|2-Polyprenyl-6-hydroxyphenol methylase|a name with a "2-" prefix}} generally indicates that the initial bit of the name is a {{w|functional group}} attached to the ''second'' position along a chemical chain (often being the carbon-carbon 'spine' of a molecule, in large-molecule organic chemistry), rather than attached to its end. Because the molecule name is (possibly deliberately) malformed, it's hard to tell what is supposed to be attached to the second carbon of what subunit. It may be intended to mimic the confusion consumers have over seemingly-similar named compounds, which may or may not have wildly differing properties. |

|- | |- | ||

|Salt and pepper to taste | |Salt and pepper to taste | ||

|{{Maybe|Not for taste, but salt can be useful}} | |{{Maybe|Not for taste, but salt can be useful}} | ||

| − | |Salt and pepper are two incredibly popular condiments which are used to enhance a dish's flavor, and "salt and pepper to taste" is a phrase found in many food recipes. But the taste of your epoxy should not be your concern. Do not eat epoxy. However, salt | + | |Salt and pepper are two incredibly popular seasonings ([[974|not condiments]]) which are used to enhance a dish's flavor, and "salt and pepper to taste" is a phrase found in many food recipes. But the taste of your epoxy should not be your concern. Do not eat epoxy that isn't labelled safe-to-eat. However, salt, sand or other fine grains are sometimes recommended to add a bit of grit to an adhesive. Generally glues or epoxies need the bonded materials to be firmly held together while the glue cures, but when first pressed together, any excess glue is squeezed out and can cause the surfaces to slip around and need to be re-aligned. Any extra friction and spacing in the epoxy can help alleviate that. |

|- | |- | ||

|Blood sample from the Gorilla Glue gorillas | |Blood sample from the Gorilla Glue gorillas | ||

|{{No}}{{Citation Needed}} | |{{No}}{{Citation Needed}} | ||

| − | |{{w|Gorilla Glue}} is a popular brand of superglue which uses {{w|gorillas}} as its mascot. | + | |{{w|Gorilla Glue}} is a popular brand of superglue which uses {{w|gorillas}} as its mascot. The comic implies that this is because the glue is produced using material taken from a fictional breed of gorillas called “Gorilla Glue” gorillas. Extracting and consuming the blood of a creature or person in an attempt to inherit some of the qualities of the 'donor' is a kind of {{w|sympathetic magic}}, so this may be suggesting that including this will give the epoxy 'the strength of a gorilla', which is commonly considered a powerful animal. Although animal products, including [https://www.sciencedirect.com/topics/engineering/blood-glue blood], have historically been used in some traditional glues, these have typically not come from gorillas, and Gorilla Glue contains no such ingredients. |

| − | |||

| − | |||

|- | |- | ||

|Stuff that bonds to every known material except yours | |Stuff that bonds to every known material except yours | ||

|{{No|Probably not}} | |{{No|Probably not}} | ||

| − | |Another common annoyance when using an adhesive is that each glue type only forms an adhesive bond with certain materials. In this case, the polymer would bond with every material except for the one you were using, causing great distress and leaving you in a fix. This is similar to "Stuff that bonds permanently to skin and nothing else" above. | + | |Another common annoyance when using an adhesive is that each glue type only forms an adhesive bond with certain materials. Poor prior research can cause much frustration when the chosen adhesive does not bond to one or both surfaces intended. In this case, the polymer would bond with every material except for the one you were using, always causing great distress and leaving you in a fix. This is similar to "Stuff that bonds permanently to skin and nothing else" above. |

|} | |} | ||

==Transcript== | ==Transcript== | ||

| − | |||

Standard 16-Part Epoxy | Standard 16-Part Epoxy | ||

| Line 98: | Line 97: | ||

[An epoxy applicator with a single push bar and sixteen differently-colored chambers, each labeled] | [An epoxy applicator with a single push bar and sixteen differently-colored chambers, each labeled] | ||

| − | Resin | + | Resin (coloured beige) |

| + | |||

| + | Hardener (mango yellow) | ||

| + | |||

| + | Filler (darker yellow) | ||

| + | |||

| + | Softener (cream) | ||

| − | + | Rosin (very light red) | |

| − | + | Stuff that bonds permanently to skin and nothing else (yellow-dark green) | |

| − | + | Stuff that will turn white and crack over a few days, for decorative appearance (light blue) | |

| − | + | Placebo (white) | |

| − | + | Minced duct tape (grey with a tint of green) | |

| − | + | Acetone Fragrance (beige-yellow) | |

| − | + | Powdered bar magnets (brown) | |

| − | + | Polyethylvinylesteracetate (blue-white) | |

| − | + | 2-Polyethylvinylesteracetate (blue-white but slightly darker) | |

| − | + | Salt and pepper to taste (light grey) | |

| − | + | Blood sample from the Gorilla Glue gorillas (red) | |

| − | + | Stuff that bonds to every known material except yours (beige) | |

| − | |||

| − | + | ==Trivia== | |

| − | Stuff that | + | The syringe of 'Stuff that will crack and turn white over a few days, for decorative appearance' has light blue fill color on part of the wrong side of the plunger. |

Latest revision as of 18:02, 28 January 2026

| 16 Part Epoxy |

Title text: Some surfaces may seem difficult to glue. But if you research the materials, find tables of what adhesives work on them, and prepare your surfaces carefully, you can fail to glue them in a fun NEW way that fills your house with dangerous vapors. |

Explanation[edit]

| This is one of 70 incomplete explanations: This page was created by boiling down a gorilla glue gorilla. Don't remove this notice too soon. If you can fix this issue, edit the page! |

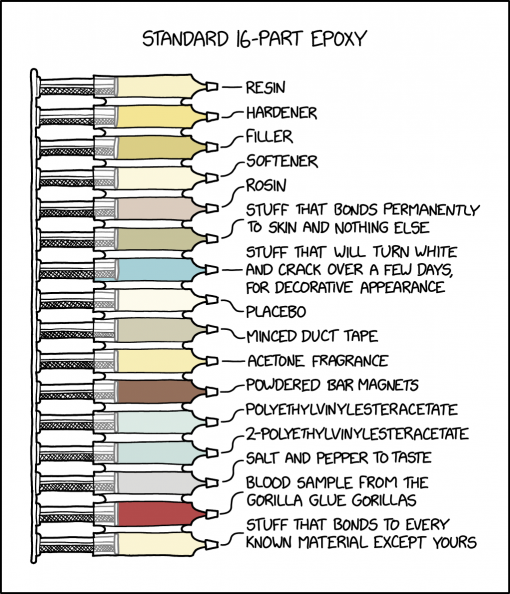

This comic refers to epoxy — substances used as adhesives, sealants, and coatings, named for the chemical substructure epoxide, which is the precursor component to these substances turning from liquids to solids.

Many types of epoxy are multi-part (usually two-part), where the components, such as resin and a hardener, are stored separately. For ease of use, this can be in parallel syringes (of equal volume, or proportionately different widths to maintain the correct mixing ratio) such that the user squeezes out both of the separate chemicals onto the initial surface, or into a container, by depressing both syringes simultaneously. The user then thoroughly mixes the components, as quickly as possible. The mixture is spread over the surface(s) to be joined or protected, and/or into the gaps to be filled, and if there are separate surfaces involved they are quickly positioned and held in place. The combined epoxy cures quickly, usually within a few minutes. This comic presents a fictitious 16-part epoxy, with the same apparent logic of parallel deposition in mind, with many components that are implausible or make fun of common problems people have when using epoxy in real life.The title text, as with a couple of the substances involved, references how not all epoxies and glues work on every material, and that applying them on others can also require special techniques or products to gain the best advantage. Some industrial or industrial-grade adhesives contain solvents (e.g. tetrachloroethylene, which is used in E6000 glue) that release harmful vapors as they cure. If used improperly, this can result in the release of chemical vapors in an enclosed space along other dangerous side-effects, while also still not adhesing as intended.

| Type | Real? | Explanation |

|---|---|---|

| Resin | Yes | A liquid which turns into a polymer when mixed with a hardener. |

| Hardener | Yes | A thick liquid which is mixed with resin to create a durable polymer which is commonly used as a glue. |

| Filler | Yes | An optional addition to the hardener and resin which changes the properties of the polymer.

Some epoxies are sold as products known as 'fillers', used to repair and cover cracks, holes, and imperfections. |

| Softener | Yes | The word is probably being used in humorous contrast to the "hardener" component, and perhaps also by analogy with laundry products that contain a fabric softener alongside a detergent. However, plasticizers are often added to polymers to make them more pliable, and thus to increase their impact resistance. These plasticizers tend to be lost over long periods of time (e.g. by evaporation or degradation), which contributes to old plastic becoming brittle. |

| Rosin | Yes | While this looks like a joke entry, this is actually a different kind of resin which is extracted naturally rather than synthesized from other chemicals. Rosin (a kind of 'flux') is one of two parts that make up rosin-core solder, used in electronic work, where the rosin is located in the center (the "core") of the wire-like solder, similar to how graphite is in the core of a pencil. When heated hot enough to melt, it cleans corrosion and oxides from the surfaces of the metal parts to be joined, creating bare metal surfaces that can be 'wet' by the solder. In rosin-core solder, the two substances are touching rather than kept completely separate, since they're both in solid form, and don't react with each other even when they're heated to melt them. In this respect they differ from common combination epoxy chemicals that will be both liquids that cure together on contact even at room temperature. Rosin is also frequently applied to the bows of string instruments like violins or cellos to improve the sound, as immortalized in the famous song "The Devil Went Down to Georgia" or the folk song Old Rosin the Beau. |

| Stuff that bonds permanently to skin and nothing else | No | One key annoyance with sticky substances is the difficulty of removing them when they are inadvertently applied to skin. In hyperbole, we have a substance here that seems to bond *solely* to skin. This may be a reference to cyanoacrylate adhesives ("super glues"), which famously bond quite aggressively to skin (sometimes to positive effect, for medical applications!) due to being moisture-activated, while often failing to bond the target materials. Still, none are known to bond to skin exclusively.[actual citation needed] |

| Stuff that will crack and turn white over a few days, for decorative appearance | Not effective as epoxy | Poor finish, where an intended smooth uniform surface cracks or discolors, can be a frustrating problem when applying epoxy mixtures to visible surfaces — especially when the problem only appears some time after you've congratulated yourself on a job well done. This humorously describes this as an intended effect, although there are situations where this truly may be intended. 'Crackle effect' is a real thing for crafters, often created by mixing paint and glue, and an adhesive used to join two pieces or repair a crack or break can be modified for a deliberately cracked or discolored surface to match the other surfaces. |

| Placebo | Not in the field of adhesives | The placebo effect happens when somebody is told that something has a certain effect, when in reality it has no mechanism of action to produce that effect. This is commonly used in medical studies to determine whether a medication actually does something, as opposed to simply having a psychosomatic effect. Using this term to describe a type of polymer suggests it would make someone believe it is gluing things together without actually doing anything, which is unlikely. Alternatively, this could refer to a component or filler that claims to serve a specific purpose while having no true benefit, merely causing the perception of benefit to the consumer (and presumably causing better reviews). |

| Minced duct tape | Not intentionally | Duct tape is widely used as a way to join and/or cover things, sometimes in contexts where an epoxy might provide a more high-quality solution. Randall is pretending that having very small pieces of tape in the mix would add to the epoxy's ability to hold things together. In reality, cutting duct tape into small pieces would weaken it and make it less effective at sticking things together. |

| Acetone fragrance | No | Acetone is a volatile solvent used in a number of glues and paints (including nail polish), but it weakens epoxy and can even be used to remove uncured epoxy. It has a strong, distinctive smell, and is actually toxic, making fragrance an odd reason for adding it to any product. It would give the epoxy a familiar "chemical smell" that people associate with industrial compounds. The use of 'X fragrance' in an ingredient list, instead of simply listing the ingredient X, usually implies that the actual ingredient is some (cheaper) substitute for X with a similar scent. Since acetone is already inexpensive, perhaps some substitute has been discovered that provides the smell without weakening this glue, though that seems unlikely given the context. |

| Powdered bar magnets | Yes, but not in resin | This might still work if the pieces could somehow be aligned correctly, as each tiny piece of magnet would still be a magnet in its own right, capable of attracting the other tiny magnets, and thus resisting tension forces. However, it would be much worse than a normal bar magnet, since the magnetic force would be weaker than those that held the original bar together. The micro-magnets would tend to clump together, which might strengthen the glue, but wouldn't help it to bond to surfaces very much unless the surfaces themselves were strongly magnetic. |

| Polyethylvinylesteracetate | Not in epoxy | This appears to be a reference to Poly (ethylene-vinyl acetate), some formulations of which can be used as the adhesive in hot-glue guns. Vinyl acetate is an ester, so the inclusion of that term is redundant. The cadence of the constructed word may also be a reference to the television episode Lucy Does a TV Commercial and its memorable product "Vitameatavegamin". It also resembles the kind of thing often seen in ingredients lists for common household products such as soaps and cleaners, which are fairly meaningless to the average person buying them. |

| 2-Polyethylvinylesteracetate | Unclear | This sounds almost exactly the same as the above item, but a name with a "2-" prefix generally indicates that the initial bit of the name is a functional group attached to the second position along a chemical chain (often being the carbon-carbon 'spine' of a molecule, in large-molecule organic chemistry), rather than attached to its end. Because the molecule name is (possibly deliberately) malformed, it's hard to tell what is supposed to be attached to the second carbon of what subunit. It may be intended to mimic the confusion consumers have over seemingly-similar named compounds, which may or may not have wildly differing properties. |

| Salt and pepper to taste | Not for taste, but salt can be useful | Salt and pepper are two incredibly popular seasonings (not condiments) which are used to enhance a dish's flavor, and "salt and pepper to taste" is a phrase found in many food recipes. But the taste of your epoxy should not be your concern. Do not eat epoxy that isn't labelled safe-to-eat. However, salt, sand or other fine grains are sometimes recommended to add a bit of grit to an adhesive. Generally glues or epoxies need the bonded materials to be firmly held together while the glue cures, but when first pressed together, any excess glue is squeezed out and can cause the surfaces to slip around and need to be re-aligned. Any extra friction and spacing in the epoxy can help alleviate that. |

| Blood sample from the Gorilla Glue gorillas | No[citation needed] | Gorilla Glue is a popular brand of superglue which uses gorillas as its mascot. The comic implies that this is because the glue is produced using material taken from a fictional breed of gorillas called “Gorilla Glue” gorillas. Extracting and consuming the blood of a creature or person in an attempt to inherit some of the qualities of the 'donor' is a kind of sympathetic magic, so this may be suggesting that including this will give the epoxy 'the strength of a gorilla', which is commonly considered a powerful animal. Although animal products, including blood, have historically been used in some traditional glues, these have typically not come from gorillas, and Gorilla Glue contains no such ingredients. |

| Stuff that bonds to every known material except yours | Probably not | Another common annoyance when using an adhesive is that each glue type only forms an adhesive bond with certain materials. Poor prior research can cause much frustration when the chosen adhesive does not bond to one or both surfaces intended. In this case, the polymer would bond with every material except for the one you were using, always causing great distress and leaving you in a fix. This is similar to "Stuff that bonds permanently to skin and nothing else" above. |

Transcript[edit]

Standard 16-Part Epoxy

[An epoxy applicator with a single push bar and sixteen differently-colored chambers, each labeled]

Resin (coloured beige)

Hardener (mango yellow)

Filler (darker yellow)

Softener (cream)

Rosin (very light red)

Stuff that bonds permanently to skin and nothing else (yellow-dark green)

Stuff that will turn white and crack over a few days, for decorative appearance (light blue)

Placebo (white)

Minced duct tape (grey with a tint of green)

Acetone Fragrance (beige-yellow)

Powdered bar magnets (brown)

Polyethylvinylesteracetate (blue-white)

2-Polyethylvinylesteracetate (blue-white but slightly darker)

Salt and pepper to taste (light grey)

Blood sample from the Gorilla Glue gorillas (red)

Stuff that bonds to every known material except yours (beige)

Trivia[edit]

The syringe of 'Stuff that will crack and turn white over a few days, for decorative appearance' has light blue fill color on part of the wrong side of the plunger.

Discussion

Woah, just reloaded it and new comic! Sick... I should probably read it now. Willintendo (talk) 20:02, 14 January 2026 (UTC)

- Explain first; read later! 82.13.184.33 10:18, 15 January 2026 (UTC)

Paint bucket fill tool strikes again. --Lycheefoxpup (talk) 20:18, 14 January 2026 (UTC)

TABLES! TABLES! TABLES! WOOOOOO!!!!!! --DollarStoreBa'alConverse 20:21, 14 January 2026 (UTC)

- Table created. However, I am a teenager and do not work in construction, so the explanations may need some work. --DollarStoreBa'alConverse 20:56, 14 January 2026 (UTC)

- Every item in this table is real. Ask me how I know. 64.201.132.210 21:34, 14 January 2026 (UTC)

- How does the placebo work? Does it just kinda mind control you?--DollarStoreBa'alConverse 21:42, 14 January 2026 (UTC)

- Every item in this table is real. Ask me how I know. 64.201.132.210 21:34, 14 January 2026 (UTC)

- Robert'); DROP TABLE Epoxy;--

- Did it work? 2001:1998:3500:42C:0:0:0:534 23:27, 14 January 2026 (UTC)

Thought for placebo adhesive: Water between two microscope slides. It'll stick real good, but it's not really glue, more... fancy pressure physics. 142.165.161.48 22:28, 14 January 2026 (UTC)

"Duck" tape, not "duct". Come on Randall, you know better than that. Yorkshire Pudding (talk) 00:08, 15 January 2026 (UTC)

- Both spellings are used. One is trademarked. 76.187.17.7 03:46, 15 January 2026 (UTC)

- Read this: https://archive.is/Fq5Js Viliml (talk) 09:36, 15 January 2026 (UTC)

- But "duct" screams folk etymology. "Duck" sounded unlikely so people though it must be "duct"...but it's a huge leap to think that a tape that some people tended to use for a/c ducts would actually be named "duct tape". Both the tape and the word "duct" are too general purpose for that. Is it known as that? Yes? Does it make sense though? Not for a second. Yorkshire Pudding (talk) 10:38, 15 January 2026 (UTC)

- To be fair, it is more commonly used for taping ducts than it is used for taping ducks 2A01:CB1C:12EF:7900:953B:FFB2:21E3:47EC 12:43, 15 January 2026 (UTC)

- Taping ducks would be quackers, though one could attempt it... --Zaphod Beebledoc (talk) 03:19, 23 February 2026 (UTC)

- Actually, it was originally named duck tape, as it was made using something called "duck fabric." This had etymology unrelated to the animal duck, from a Dutch word "doek." There were some similar tapes seeing some use with that name beforehand, but it became common as during WWII, a kind of it was adopted by the military for sealing ammunition crates, and it's availability led to soldiers widely using it for other purposes. After the war, it was then sold to civilian markets. Common use on air ducts led to it being made in the same gray color, and being labeled "duct tape." Many had forgotten the original name when in the 70's someone decided to call it that again while advertising it with a cartoon duck picture.--2600:100A:B10C:6B2E:EC47:CF99:9B14:1C81 08:00, 16 January 2026 (UTC)

- To add on to that point, the most popular use for pipe cleaners (other than elementary school craft projects) is to clean pipes, so it's not that much of a stretch. --DollarStoreBa'alConverse

- This is also the etymology of Duck Dynasty who were originally duct hunters: that is, they were federal agents who snuck into the ductwork of large facilities, and hunted evil spies throughout the ducts. Eventually they found that the ductwork caused so much ricochet for their shotgun blasts—and frequently foiled by duct decoys—that they decided to take the duct hunting outdoors. Elizium23 (talk) 09:03, 20 January 2026 (UTC)

- To be fair, it is more commonly used for taping ducts than it is used for taping ducks 2A01:CB1C:12EF:7900:953B:FFB2:21E3:47EC 12:43, 15 January 2026 (UTC)

- But "duct" screams folk etymology. "Duck" sounded unlikely so people though it must be "duct"...but it's a huge leap to think that a tape that some people tended to use for a/c ducts would actually be named "duct tape". Both the tape and the word "duct" are too general purpose for that. Is it known as that? Yes? Does it make sense though? Not for a second. Yorkshire Pudding (talk) 10:38, 15 January 2026 (UTC)

- Ducks? Thanks. Oh sorry, wrong webcomic. 2A02:2455:1960:4000:F1E8:367:E9A3:2FC7 10:43, 16 January 2026 (UTC)

Now I'm wondering what the properties of a powdered bar magnet would even be, if each individual piece continued to be magnetic. 2405:201:E010:1029:2C1E:1669:FA92:85DE 00:44, 15 January 2026 (UTC)

- A magnetic powder stops being diamagnetic. All the north poles clamp onto a south pole, so the magnetic fields essentially all cancel. You end up with "lump of magnetic powder", not "one big magnet" or "powder you can disperse in a liquid." Nitpicking (talk) 03:32, 15 January 2026 (UTC)

- But all the little pieces of magnets are still full magnets with a north and a south pole. Magnetic monopoles have, so far, not been observed in practice. --Coconut Galaxy (talk) 06:32, 15 January 2026 (UTC)

- Want to know something weirder? I was shopping today for a toner cartridge, and found that they still manufacture (for the same printer I own) MICR ink and toner. A little disappointed to find out, it’s just magnetizable iron oxide, but more exciting than normal toner! Elizium23 (talk) 09:09, 20 January 2026 (UTC)

- But all the little pieces of magnets are still full magnets with a north and a south pole. Magnetic monopoles have, so far, not been observed in practice. --Coconut Galaxy (talk) 06:32, 15 January 2026 (UTC)

So, the 2-poly(etc) seems to me to suggest that instead of being "-vinyl-ethyl-vinyl-ethyly-" polimerisation, with the links between both 'ethyl-like' backbone subcomponents being from opposite ends of the respective subunit carbon-pairing, it'd more likely now be considered as a polymethyl-group with a methyl (or methylene) group as the now unused onward '1-'site, hanging free of the new polychain. I'd have to check the bond-geometries, though to see if it would even work. (Ignoring the obvious problem with the made up name.) 92.23.2.208 01:44, 15 January 2026 (UTC)

- Ph.D. chemist and AI to the rescue - the 2 makes no sense here, and poly-2-vinyl neither, as substitution pattern 2=1 here. 2A02:2455:1960:4000:F1E8:367:E9A3:2FC7 10:47, 16 January 2026 (UTC)

I feel like the Polyethylvinylesteracetate is a joke about how polymer names are often long and gibberish-sounding. Potatocakethrow (talk)

Rosin is also used soldering, which might be relevant to adhesives. Soldering is used to join pipes, among other things. Nitpicking (talk) 03:32, 15 January 2026 (UTC)

- >"Rosin is also used soldering, ...to join pipes" Plumbing (pipes) soldering more often uses "acid flux" (Zinc Chloride and similar), not rosin which is used in electronics and jewelry. --PRR (talk) 05:48, 15 January 2026 (UTC)

While it's less common in glues than other animal products (such as skin, bones, or cheese), blood-based glues are (or historically were) a thing. Citation: https://www.sciencedirect.com/topics/engineering/blood-glue Gorillas would not be a suitable source of this blood, though. 178.251.89.99 (talk) 07:09, 15 January 2026 (please sign your comments with ~~~~)

The traditional song "Rosin the Bow" may be less well known than "The Devil Went Down to Georgia", but rosin is in the title. 87.75.47.93 10:46, 15 January 2026 (UTC)

The main page has been vandalized with pornography 65.35.147.191 (talk) 15:13, 15 January 2026 (UTC) (please sign your comments with ~~~~)

- I've asked Kynde to block the vandal but I don't know how long it will take (or if its even possible) --DollarStoreBa'alConverse 14:46, 16 January 2026 (UTC)

- Firstly, this discussion page is for a specific comic and has nearly nothing to do with main page, especially after a couple of days. Secondly, the vandal activity is so obvious that I think everyone notices (that is the very point) and so it's probably not necessary to comment on every instance of it. Thanks. Elizium23 (talk) 08:45, 22 January 2026 (UTC)

How would you even squeeze that thing Yaokuan ITB (talk) 18:09, 15 January 2026 (UTC)

- Really hard. 47.141.37.161 08:16, 16 January 2026 (UTC)

sodium bicarbonate can be used on cyanoacrylate glues as an accelerant and hardener. Pergaps salt can play a similar role in some epoxy mixes? 131.255.152.112 18:27, 15 January 2026 (UTC)

Has anyone else noticed the coloring error on the stuff that cracks after a few days? Some of it is leaking out the back of the syringe in a way that doesn't look intentional. 66.42.178.247 13:35, 16 January 2026 (UTC)

- Woah, you're so right. That ought'a be put in a trivia section. Willintendo (talk) 17:35, 16 January 2026 (UTC)

- It looks like it has some exposure to the surrounding air. If Randall is clever enough he might eventually change it to cracked white to better match the background IAmADroid (talk) 04:32, 17 January 2026 (UTC)

i think the Filler refers to just extra stuff of some sort to essentially pad out the material and make it cheaper, as opposed to actual being useful 129.64.0.36 06:14, 21 January 2026 (UTC)idk

“Stuff that bonds permanently to skin and nothing else”

“Stuff that bonds to every known material except yours”

Hey, I think I have those in my house!MikeTheNewGuy (talk) 01:19, 25 February 2026 (UTC)